Charpy Impact Test Formula

Fe 075 Ni. Grade 420 stainless steel is a high-carbon steel with a minimum chromium content of 12.

It contains the chemical elements carbon and hydrogen.

. Amendments to Sri Lanka Standards. Abrasion Resistance HDPE pipes have excellent resistance to. 4 HDPE Product Information 4.

Charpy Impact notched 0 C 14 Kjm² 16 Kjm² Hardness Shore D - 60 - Carbon Black Content 2 2 Brittleness Temperature -70 C -70 C ESCR 10 lgepal 10000 h 10000 h Thermal Stability 210C 15 min 15 min. Draft Sri Lanka StandardsAmendments For Public Comments. There are 4 steps for impact test exemption assessment.

When heated or deformed at a rapid rate due. Like any other stainless steel grade 420 can also be hardened through heat treatment. For example a class 30 gray iron which was typical for an engine block has a nominal tensile strength of 30000 psi 207 MPa.

Introduction Key Properties Composition Mechanical Properties Physical Properties Grade Specification Comparison Possible Alternative Grades Corrosion Resistance Heat Resistance Heat Treatment Welding Machining Applications. 111 The code applies to ships regardless of their size including those of less than 500 gross tonnage engaged in carriage of liquefied gases having a vapour pressure exceeding 28 bar absolute at a temperature of 378 c and certain other substances as shown in Chapter 19 when carried in bulk. No less extreme is the RM UP-01 Ferraris jaw-dropping price tag of US188 million dollars in keeping with the brands reputation for outrageously expensive watches.

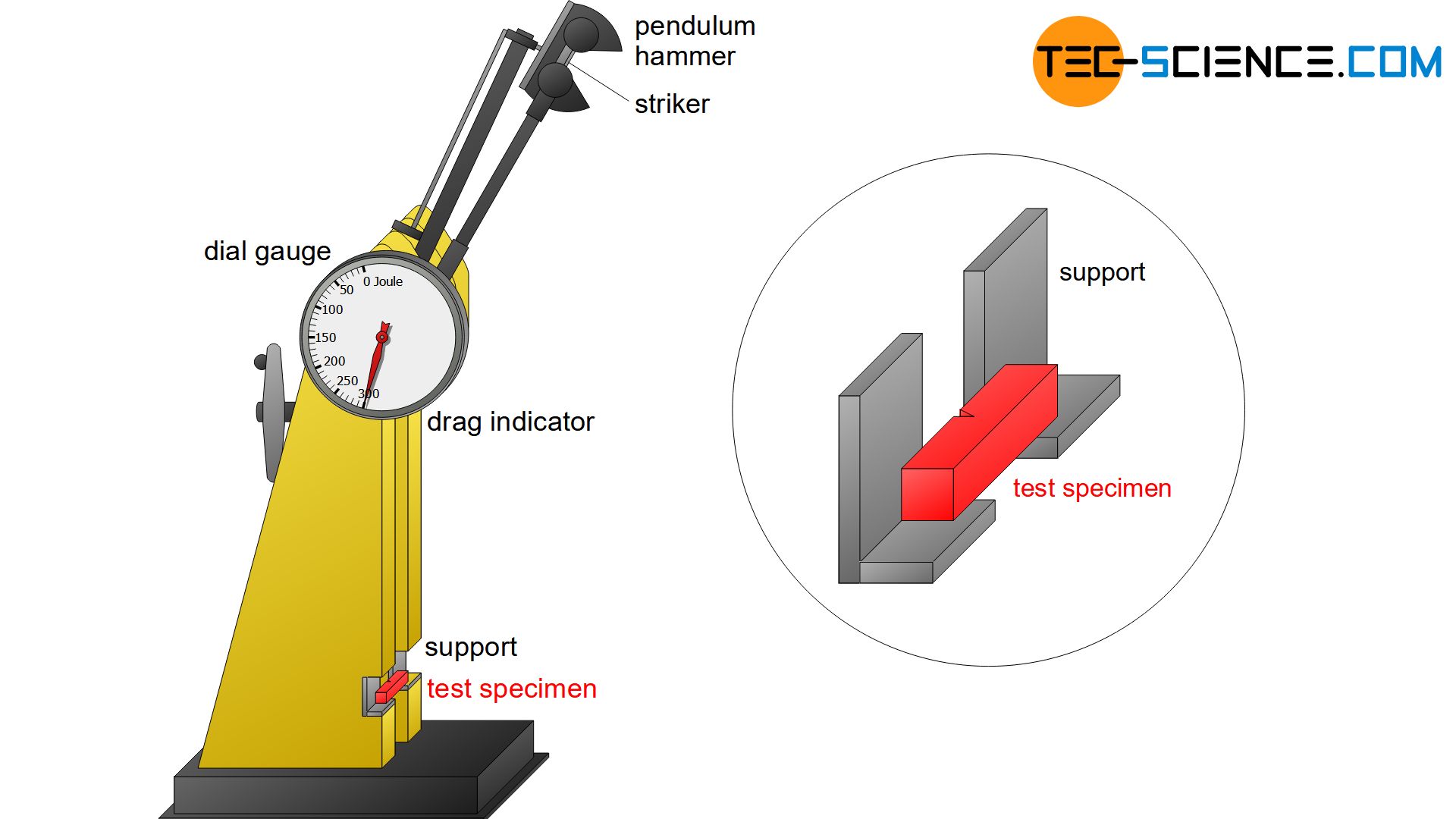

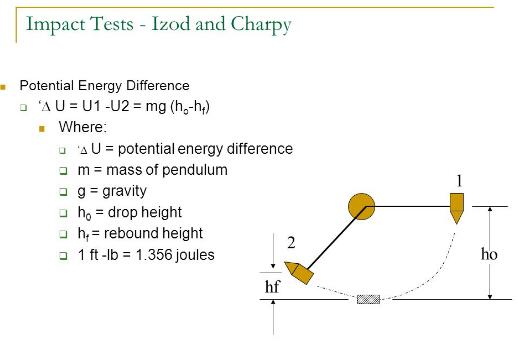

The Charpy impact test just like any impact testing method determines the toughness of materials by measuring the amount of energy absorbed by a specimen as it fractures while being struck by a. The various product standards specify minimum values of impact energy for different sub-grades of each strength grade. The SABS 1431 range of structural steel grades is readily weldable by means of the usual metal-arc processes.

You might be exempted in the first second or third steps and might not be. Fe. SRMs 2092 2096 209.

Low High and Super High-Energy Test Specimens for Charpy V-Notch Impact Testing Machines May 14 2001. NOTE Test Methods A 923 Method B applicable to some duplex austenitic-ferritic stainless steels as listed in Test Methods A 923 uses a Charpy impact test for the purpose of determining the absence of detrimental intermetallic phases. You need to know these steps.

It offers good ductility in its annealed state and excellent corrosion resistance. When welding thick plates reference should be made to BS 51351984 Specification for arc welding of carbon manganese steels Carbon equivalent CE values should be calculated from the values of the chemical composition indicated on the test certificates for. A convenient measure of toughness is the Charpy V-notch impact test - see image on the right.

Gray iron is specified by a class number which corresponds to the nominal tensile strength of the alloy. Polystyrenes chemical formula is C 8 H 8 n. Method B specifies a test temperature and acceptance criterion expressed as impact energy for each type of.

Low-Energy Charpy V-Notch Specimens Self-Verification 8-mm Striker Lot LL-160. Based on the ASME impact test requirement you need to make assessment to see that either your pressure vessel is exempted from impact testing or you need to carry out the test. This makes it very easy for cracks to propagate through the material which inhibits strength ductility and impact strength fracture toughness.

For instance in terms of data network a good SNR signal-to-noise ratio is 20 dB or aboveAnd if the network is meant to use voice applications then it needs to be 25 dB or above. Impact Test Test designed to determine the resistance of metal to breakage by impact usually by concentrating the applied stress to a notched specimen2 A test to determine the behavior of materials when subjected to high rates of loadingusually in bending tension or torsion. Low and High-Energy Test Specimens for Charpy V-Notch Impact Testing Machines February 19 1993.

A good signal-to-noise ratio is one that has signal levels much higher than noise levels as the greater the noise levels the more disruption is causedA low signal-to-noise ratio means that. The quantity measured is the energy absorbed in breaking the specimen by a single blow as in the. TYPICaL PHYSICaL PrOPErTIES Of HDPE PIPE 1.

Since the molecules consist of thousands of atoms the cumulative attractive force between the molecules is large. The materials properties are determined by short-range van der Waals attractions between polymers chains. This test measures the impact energy required to break a small notched specimen at a specified temperature by a single impact blow from a pendulum.

Charpy Impact Test Tec Science

000509 Calculation Of Absorbed Energy On Charpy Impact Test Izod Impact Strength Test

Diagram Of Charpy Impact Test The Hammer Is Released At A Swings To B Download Scientific Diagram

Comments

Post a Comment